Technology services

With Access to additive manufacturing technologies, we can create at the pace of design. Your concepts will come to life real time.

FDM Printing

Fused Deposition Modeling (FDM) printing is an essential tool for bringing innovative solutions into reality. This 3D printing method utilizes a thermoplastic material that is melted and deposited layer by layer to create a 3D object. FDM printing allows us to quickly and cost-effectively create functional prototypes, enabling us to test and refine your product designs before moving into full-scale production.

With FDM printing, we can easily produce complex geometries and intricate designs that would be difficult to achieve using traditional manufacturing methods. This technology provides a level of flexibility that allows engineers and designers to make design modifications quickly, reducing lead times and costs associated with product development.

FDM printing's capabilities also extend to the ability to create multiple iterations or variations of a design in a short amount of time. This feature is particularly useful when working with clients who require a rapid turnaround on the design process. FDM printing allows for the production of multiple versions of a product that can be evaluated and refined in a fraction of the time it would take with traditional manufacturing methods.

In addition to prototyping, FDM printing has become a valuable tool for creating jigs, fixtures, and tooling for production lines. This technology provides us with a fast and efficient method of creating custom parts that meet the specific needs of our clients.

By utilizing FDM printing in our product development processes, clients can reduce costs, improve efficiency, and bring innovative solutions to the market faster than ever before.

MSLA Resin Printing

Our 3D printing capabilities allow us to create high-resolution, detailed objects with precision and accuracy. This cutting-edge technology provides us with the ability to bring your designs to life and help you visualize your ideas in a tangible form.

MSLA 3D printing is a versatile technology that allows us to create detailed, functional parts with speed and precision. This type of 3D printing utilizes a liquid resin that is cured with a UV light, resulting in high-quality, detailed prints that are ideal for product development. With MSLA printing, we can quickly create custom durable and functional parts that match your exact specifications, enabling you to test and refine your designs more efficiently than ever before.

One of the primary benefits of MSLA printing is its ability to create parts with high accuracy and detail. This level of precision allows for the creation of parts that are nearly indistinguishable from the final product. This is especially useful in product development, as it allows companies to test and refine their designs before investing in costly production tools.

Another benefit of MSLA printing is its speed and efficiency. This technology allows for the creation of complex parts in a matter of hours, rather than days or weeks. This speed enables companies to iterate and refine their designs more quickly, resulting in faster time to market.

Overall, MSLA 3D printing offers a powerful set of capabilities for companies that offer product development services. Its speed, accuracy, and versatility make it an ideal tool for creating functional, high-quality parts that match clients' exact specifications.

We can work with you to refine your design and make any necessary modifications to ensure that the final product meets your specifications. We use high-quality materials to produce durable, long-lasting parts that are capable of withstanding the rigors of real-world use.

2D CNC Machining

2D CNC machining is a manufacturing process that utilizes computer-controlled tools to cut materials with high precision and accuracy. It is particularly useful for creating small to medium-sized metal components with complex geometries. As a product development firm, we rely on 2D CNC machining to produce parts for various industries, including aerospace and medical.

During the machining process, a computer program directs the cutting tool to make precise cuts into the material. The program determines the tool path, speed, and cutting depth based on the part design, ensuring a high level of accuracy and repeatability. With 2D CNC machining, we can produce intricate parts with tight tolerances and excellent surface finishes.

One of the key advantages of 2D CNC machining is its ability to produce complex geometries with relative ease. The process is particularly well-suited for creating components with irregular shapes or internal features that are difficult to achieve using traditional machining methods.

2D CNC machining is a versatile process that can be used to create parts from a range of metals, including aluminum, steel, and titanium. Depending on the material and application, we can use a variety of cutting tools and techniques to achieve the desired result. For example, we may use a milling tool to remove material from the surface of a part, or a drilling tool to create holes of various sizes and shapes.

Laser Engraving

We offer laser engraving capabilities that are ideal for prototyping various products. With our laser engraving equipement, we can easily etch intricate designs onto a wide range of materials, including wood, plastic, and metal. Laser engraving is a high precision method that uses a focused beam of light to create detailed designs, logos, or text on a product's surface. This process is perfect for prototyping because it allows for quick and efficient testing of various designs, without the need for expensive molds or tooling.

Our laser engraving capabilities also allow us to easily make modifications to designs during the prototyping phase. We can quickly and easily adjust the design based on customer feedback, ensuring that the final product meets all of their requirements.

In addition, laser engraving is an environmentally friendly process that produces little to no waste. This is because the process does not require any chemicals or inks, and the only material that is removed is the small amount of material that is being engraved.

Overall, our laser engraving capabilities provide a cost-effective and efficient way to prototype products with intricate designs. We can quickly and easily make modifications during the prototyping phase, ensuring that the final product meets all customer requirements.

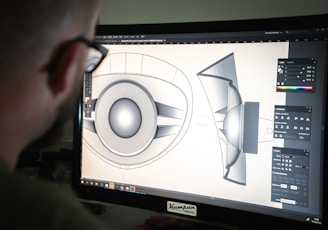

3D Modeling

3D modeling is a powerful tool that enables us to create highly accurate and detailed designs of complex components. It is particularly useful for visualizing your product realtime. As a company that offers product development services, we rely heavily on 3D modeling to create high-quality parts and prepare our prototypes.

With 3D modeling, we can create virtual representations of parts and assemblies, allowing us to visualize and test them in a simulated environment. This helps us identify any potential design flaws or issues before the manufacturing process begins, reducing the likelihood of errors and the associated costs. Additionally, 3D modeling allows us to iterate on designs quickly, making changes as needed without having to create physical prototypes.

The process of 3D modeling involves using specialized software to create a digital model of the part or assembly. The software enables us to manipulate the model in a variety of ways, such as adding or removing features, adjusting dimensions, or changing the material properties. This enables us to create highly detailed and accurate designs that meet our clients' specifications.

One of the key benefits of 3D modeling is its ability to facilitate rapid prototyping. By using 3D models to create physical prototypes, we can quickly test and validate our designs before committing to full-scale production. This helps us identify any issues early on and make the necessary adjustments, reducing the overall time and cost of the product development process.

Partner Solutions

Our partners provide an array of cutting-edge manufacturing services that enable us to bring our innovative product designs to life. They expand our capabilities to wide variety of manufacturing processes, including metal 3D printing, 6-axis CNC machining, and injection molding, to name just a few.

One of the key benefits of working with our partners is the range of materials they offer. They provide access to a vast selection of high-quality materials, including metals, plastics, and elastomers, each with unique properties and characteristics that make them ideal for specific applications.

In addition to their extensive material selection, our partners are also well-versed in the latest manufacturing technologies. Their expertise allows them to offer advanced manufacturing solutions, such as rapid prototyping, which enables us to quickly test and validate our designs before committing to full-scale production.

Perhaps most importantly, our partners' commitment to quality is unparalleled. They have rigorous quality control measures in place to ensure that all parts and components meet our exacting standards. From design to delivery, our partners are dedicated to providing high-quality, reliable manufacturing services that enable us to bring our innovative ideas to fruition.

In summary, our partners provide a wide range of cutting-edge manufacturing services that enable us to bring our product designs to life. Their expertise in advanced manufacturing technologies, extensive material selection, and commitment to quality make them an essential partner in our product development process.